Concrete Wall Forming 25KPA Building Aluminum Formwork Profiles

Product Details:

| Place of Origin: | Langfang,Hebei,China |

| Brand Name: | Goomay |

| Certification: | ISO9001:2015 , ISO14001:2015 , ISO45001:2008 |

| Model Number: | GM-JZMB-11 |

Payment & Shipping Terms:

| Minimum Order Quantity: | MOQ 2000KGS For Initial Order,the quantity could be negotiable |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Inside:packed with protective film to protect each piece. Outside: Bulk Quantity , Thermal Shrinkage Bags , Whole Craft Paper |

| Delivery Time: | After drawings confirmed,4-7days moulds ready , after samples approved , 7-10days delivery for 200TONS |

| Payment Terms: | 30%deposit+70% against BL copy, D/P, L/C |

| Supply Ability: | 5000T MONTHLY |

|

Detail Information |

|||

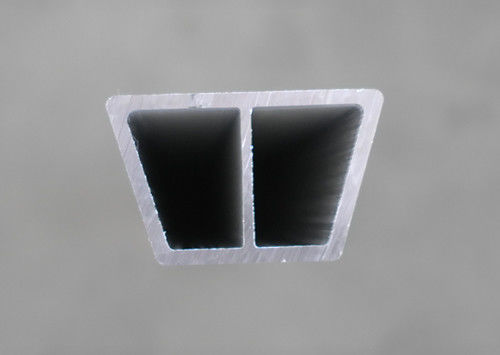

| Product Name: | Aluminium Template Profiles , Building Formwork Profiles | Material: | China Alminium Origin Ingot 6005-T6 , 6061-T6 |

|---|---|---|---|

| Surface Treatment: | Mill Finish , Anodized Silver | Length:: | 6M - 13M Or Customized Length |

| Wall Thickness: | 2MM-15MM Or Customized Wall Thickness | Characters: | Light Weight,Easy-Installation,Recycled |

| Certificates: | ISO9001:2015 , ISO14001:2015 , ISO45001:2008 , Hebei Provincial Qualified Cerificate | Application: | Concrete Construction , Real Estate Construction |

| Highlight: | 25KPA Building Aluminum Formwork Profiles,Concrete Construction Aluminum Profiles,Wall Forming Building Aluminum Formwork Profiles |

||

Product Description

Aluminum Alloy building Formwork/Aluminum Template/Concrete Formwork

Description

We have adopted a more advanced system. The strength and rigidity of aluminum alloy formwork system are improved by optimizing the section of aluminum alloy formwork and surface powder coated treatment.

So, you will be able to purchase higher quality products at a lower price.

Product Parameters

| Product Name | Aluminium Template Profiles, Building Formwork Profiles | |

| Material | China Alminium Origin Ingot 6005-T6 , 6061-T6 | More toughness |

| Surface Treatment | Mill Finish , Anodized Silver | High corrosion resistance |

| Characters | Light Weight, Easy-Installation, Recycled | Save time and manpower |

| Certificates | ISO9001:2015 , ISO14001:2015 , ISO45001:2008 | National quality certification |

| Application | Concrete Construction , Real Estate Construction |

Aluminum alloy formwork system

Supporting system:

Primary support: adopt advanced early removal technical support system to ensure that the construction cycle of each structure is controlled within 4 ~ 5 days. The allowable vertical bearing capacity is up to 20 ~ 25KPA.

Bidirectional bracing:

Realize the three-dimensional adjustment function, while ensuring the verticality and flatness of the vertical members (walls, columns), it can strengthen the horizontal rigidity and bearing capacity of the vertical members (walls, columns) to resist the lateral direction caused by pouring concrete pressure.

Panel system:

It is made of extruded aluminium alloy profiles (6061-T6, etc.), with light weight, high strength and good integrity, thus ensuring easy installation and repeated flipping of the horizontal plate.

Fastening system:

Within the range of conventional storey height (2.8 ~ 3.2M), the back flute system adopts the design principles of locally strengthening 4 parts of inner wall, 5 parts of outer wall, openings and floating platforms, etc., so as to ensure the formwork system Overall strength, stiffness and stability.

Accessory system:

Pins, pins, bolts and other hardware accessories are all made of high-quality products, and the performance and processing accuracy meet the relevant specifications and customer requirements.

Economic benefit

The biggest cost advantage of the aluminum alloy template system is that it can be reused multiple times. At present, the standard template is used more than 300 times, and the damaged template can be recycled and re-casted.

At the same time, due to the high molding quality of the aluminum template, it can achieve the effect of plaster-free turbulence, saving a lot of cement, sand, water and mortar production, transportation and plastering labor costs, and its economic benefits as the number of repeated use increases The manifestation becomes more obvious.

Reduce wood consumption and protect forest resources.

The aluminum alloy formwork can be used repeatedly for many times. After being damaged, it can be returned to the furnace and remelted. All of them are reused, which greatly reduces the waste of wood.

Caring for life and paying attention to safety.

Achieve safe and civilized low-carbon construction and reduce site safety accidents.

Save the use of river sand and protect water and soil resources.

Due to the high forming quality of aluminum alloy formwork, the effect of plastering can be avoided, and a large amount of labor cost can be saved in the production, transportation and plastering of cement, sand, water and mortar.

Improve efficiency and reduce energy consumption.

The use of aluminum alloy formwork has high construction efficiency and reduces energy consumption in building construction.

Construction advantages

1. Good system integrity

The overall casting is sub-molded, and the structure is safer.

2. High construction efficiency and short construction period

Early demoulding systems required only one set of templates.

3. Good construction quality

High quality concrete shapes: high precision in verticality, flatness, levelness and section size.

The concrete surface has a good look and feel: the effect of white concrete can be achieved without plastering.

4. Reduce the use of vertical transport machinery

Except for the first formwork going upstairs and the last time going downstairs, lifting equipment is used, all subsequent manual transfers are used.

5. Solve the shortage of skilled workers on the construction site

The installation is simple, and the general workers can carry out the installation of aluminum formwork after simple training.

6. Safe and civilized construction

The support system is simple and convenient, with large on-site operation space, personnel movement, smooth material handling, clean and safe construction surface.

There is no construction waste, no need to store and clean up, and the construction site is easy to manage.